Policy inconsistency, official bureaucracy, low capacity utilisation, dwindling demand, FX scarcity and high interest rates are among the challenges encountered by automotive plants in Nigeria.

Policy inconsistency, official bureaucracy, low capacity utilisation, dwindling demand, FX scarcity and high interest rates are among the challenges encountered by automotive plants in Nigeria.

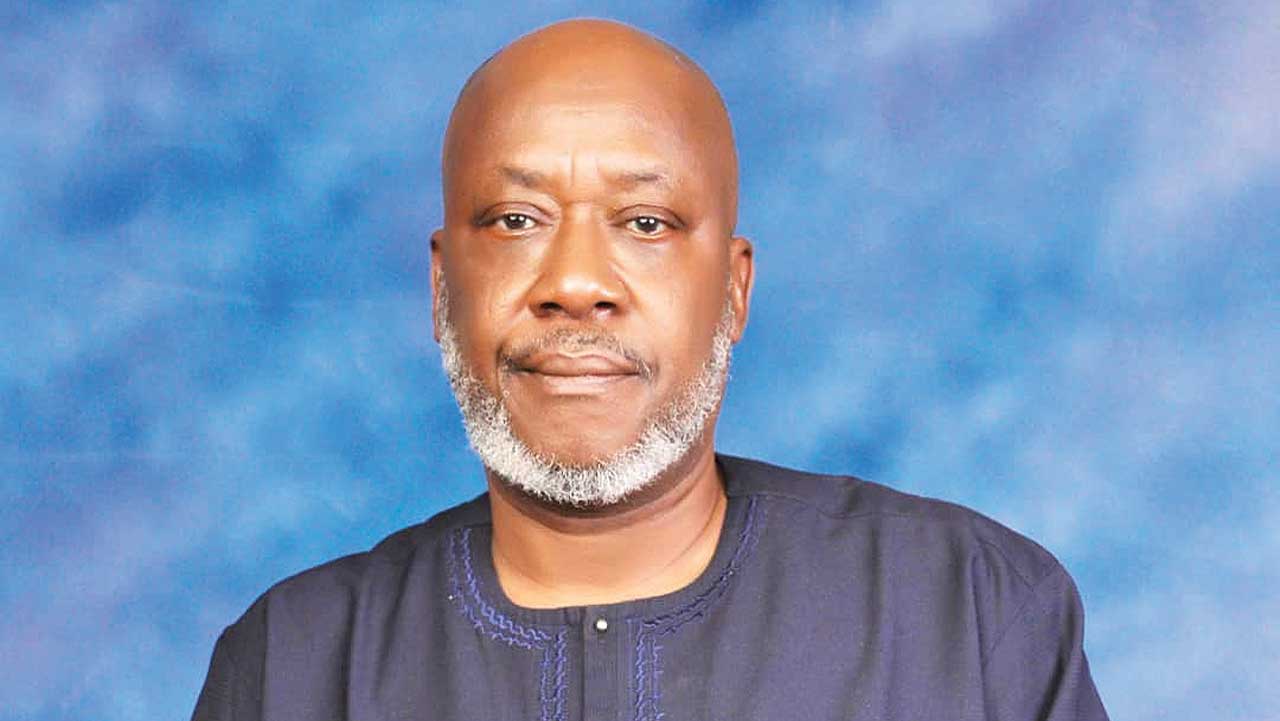

The challenges were identified by automakers during a tour of some assembly plants in Lagos and other locations in the South-West by the Director-General of the National Automotive Design and Development Council (NADDC), Joseph Osanipin.

At both Honda Automobile West Africa Ltd (HAWA) at Ota and DAG Industries Nigeria Limited (assembler of Bajaj motorcycles and tricycles) in Lagos, the DG was informed that the factors interplay to hamper growth and development in plants.

Speaking during the visit, Managing Director, HAWA, Takashi Nakajima, mentioned the falling purchasing power as a major challenge the plant is facing.

Nakajima, therefore, called for stricter restrictions on the importation of used vehicles, and the provision of auto finance with favourable interest rates to stimulate demand, adding that HAWA has enough installed capacity to satisfy the market.

In a presentation, the head of sales and marketing at HAWA, Remi Adams, listed, among other hitches, the daunting hurdles the company faces in the renewal of its manufacturer certificate required in clearing goods at the ports.

He also complained of high duties on imported components and fully built cars, delays in clearing and difficulties encountered in getting the Customs to release vehicles, which leads to demurrage, as challenges.

Adams lamented a situation where duly imported vehicles are still impounded by the Customs on the road after they are cleared.

Apart from the assembly of vehicles, which commenced about 10 years ago, a different section of the Honda plant also assembles motorcycles for distribution to different parts of the country.

At Bajaj plant, the biggest in Africa, Plant Head, Mazhar Abbas, said the range of modern equipment was installed to produce about 2,000 motorcycles a day and about 1,000 tricycles a month. He lamented that due to demand fluctuations, only a fraction of the capacity is currently being utilised.

Prohibition of the use of motorcycles for commercial purposes in various parts of the country, he said, has reduced the demand, which has affected production.

Reacting to some of the issues raised, including Customs-related ones, the DG said that proper synergy with relevant ministries and agencies is needed to address some of the challenges in the automotive industry.

“We need to work with other agencies; we need to work with other ministries and apply an inter-ministerial approach in creating desks for the stakeholders so that when there are challenges, they will be able to report immediately instead of moving from one agency to the other,” he said.

The NADDC DG said he embarked on the tour of the assembly facilities to ascertain the available capacities and potentials as the industry begins the implementation of the Nigerian Automotive Industry Development Plan (NAIDP 2023-2033) with an inter-agency and inter-ministerial committee inaugurated recently.