The recent announcement by the Federal Government to launch the first batch of approximately 5,600 “palliative” compressed natural gas (CNG) and electric vehicles ahead of President Bola Tinubu’s first administration anniversary has sparked debate within the Nigerian automotive industry.

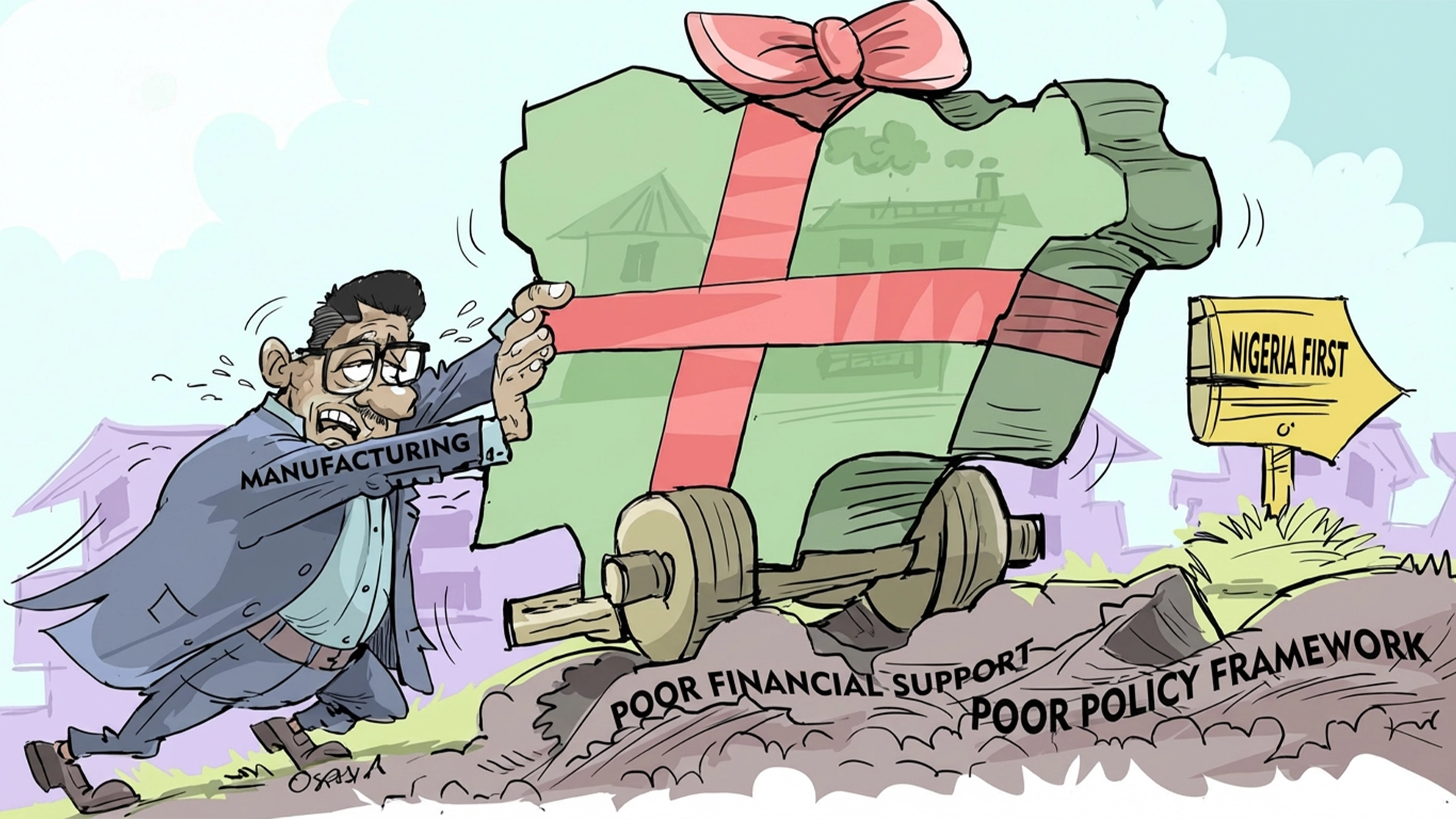

Stakeholders are questioning the decision to opt for semi-knock-down (SKD) assembly, which is effectively importing vehicles fully built and assembling them locally as opposed to patronising local manufacturers.

This move, according to industry insiders, contradicts the principles of the Nigerian Automotive Industry Development Plan (NAIDP-2023).

The Special Adviser to the President on Information and Strategy, Bayo Onanuga, in a statement, announced the procurement of the vehicles and 20,000 CNG conversion kits, valued at about N100 billion, as part of efforts to mitigate the impact of fuel price increases following the removal of petrol subsidies last year.

Onanuga highlighted that the PCNGI committee’s plan to deploy “CNG buses and tricycles aims to have at least one million natural gas-driven vehicles on Nigerian roads by 2027,” marking a significant transition in the country’s transportation sector.

The implementation involves four plants – JET Motors, Mikano Motors, Kojo Motors, and Brilliant EV, located across the country, assembling the SKD components of the CNG buses.

Notably, JET Motors in Lagos has been tasked with delivering 200 units before the anniversary of the Tinubu administration.

However, this announcement has raised concerns among auto manufacturers.

Critics, including key industry players, are sceptical about the criteria used by the PCNGI committee in selecting the beneficiary auto plants and the rationale behind choosing the SKD option, which is seen as minimally beneficial to local industry development.

Notably, except for Brilliant, which is confirmed not to be a member of the Nigerian Automotive Manufacturers Association (NAMA), all other beneficiaries are recognised within the industry.

The preference for SKD assembly, almost akin to importing fully built vehicles and merely assembling them locally, has been widely criticised as contrary to the spirit of NAIDP-2023.

The Managing Director of D.V.C Ltd and former Chairman of ALCMAN, Dr. David Obi, expressed disappointment over the government’s inconsistent policies in the auto sector.

He noted the historical efforts of companies like PAN Nigeria, Kaduna; ANAMMCO, Enugu; Volkswagen, Lagos and Innoson Vehicle Manufacturing Company Ltd (IVM) in Nnewi, which previously engaged in CKD (complete knock-down) manufacturing, adding significant local value.

“Are we moving forward or going backward?” questioned Obi, who supplied chemicals and sealants to some of these companies, criticising the regression to SKD.

Obi also contested the planned production of 6,000 units this year and one million by 2027, based on SKD, highlighting the irony given NAIDP-2023’s aim to transition from SKD to CKD manufacturing over the next decade.

According to him, “coupling” vehicles on SKD basis, is also an irony considering that the NAIDP-2023 for which an inter-agency and inter-ministerial committee was inaugurated early this month by the Industry Trade & Investment Minister, Dr. Nkiruka Uzoka-Anite.

He said this is promoting “the transition of SKD to CKD type of automotive manufacturing over the next 10 years.

The General Manager of a company that has been instrumental in the success of a Japanese brand in the local auto industry, who requested anonymity, voiced concerns about the seeming disconnect between NAIDP-2023’s directives and the contracts awarded, questioning the selection process and transparency of the bidding.

He further remarked, “How were the companies that won the contracts even selected? Was there a transparent bid process? If so, how come an entirely new assembly plant that is yet to commence operation was awarded the contract for the assembly of tricycles? What roles are the existing and popular bus assemblers and manufacturers with pedigree playing in the entire presidential CNG initiative?”

The Managing Director of Transit Support Services Ltd (TSS), Frank Nneji, took a broader perspective, emphasising the benefits of assembling vehicles locally, whether through CKD or SKD, as advancing local production capabilities and fostering technical transfer.

Despite some industry stakeholders questioning the bidding process and the expertise of the committee members, Nneji confirmed previous competitive bids in which TSS participated, underscoring the experts’ right to select based on established criteria.

The stakeholders argued that since the “experts” are not automakers, and may not have even heard of the Auto Policy (NAIDP 2023), it will be difficult for them to know the difference between SKD and CKD or who can produce what vehicle.

Amidst these controversies, managers from PAN, Kaduna, and ANAMMCO, Enugu, revealed they were not invited to bid, while the Chairman of Innoson Vehicle Manufacturing Co Ltd, Dr. Innocent Chukwuma, expressed dismay at being overlooked despite Innoson’s track record in CNG bus production.

Chukwuma further stated that Innoson has been the sole auto manufacturer conducting CKD production of CNG buses of various sizes for approximately two years.

He questioned why the company was forgotten when the time came to bid for the contract.

The Head of Communications at Innoson Vehicles, Cornel Osigwe, called for clarity on the selection process, advocating equal bidding opportunities for all capable manufacturers.

Osigwe stated that Innoson has repeatedly demonstrated its capability to produce CNG-powered vehicles.

He noted that the Nnewi plant began manufacturing CNG buses well before the discussion of oil subsidy removal commenced and expressed concern about being completely excluded from the process.

Osigwe, through a press release, urged the committee to clarify whether preferred bidders existed and why auto plants with substantial capacities to manufacture buses on CKD bases were not offered equal bidding opportunities.

The press release added, “For over two years now, Innoson has been manufacturing various models of CNG buses. We made history as the first and, thus far, the only manufacturer of CNG/LNG-powered vehicles in Nigeria, earning several recognitions, including awards from The Sun Publishing, Silverbird, and the Nigeria Auto Journalists Association (NAJA) in 2023.”

“It is also noteworthy that the receipt of the Quality Management Certificate and the MANCAP Certificate from the Standards Organisation of Nigeria (SON) in 2023 confirms our commitment to high international quality standards in our vehicle production.”

A member of the NAMA Board of Directors and Chief Operating Officer of ANAMMCO, Bennett Ejindu, lamented the missed opportunity to stimulate the auto industry, which has been in a prolonged decline, through the procurement of thousands of CNG and electric vehicles.

Ejindu attributed the failure to adopt the CKD option to the absence of a NAMA member on the Presidential committee.

He reasoned that a NAMA representative on the committee would have likely addressed this oversight by suggesting that Nigerian automotive plants produce the vehicles to rejuvenate the industry.

He emphasised that the primary concern is not whether Innoson, ANAMMCO, or PAN bid and won the contract to produce the buses, but that the contracts are executed in a manner that maximizes their impact on the industry.

Ejindu pointed out that companies that received orders but lacked the necessary manufacturing capacity should consider subcontracting to plants with greater capabilities.

He referenced a past collaboration between his company and TSS to assemble thousands of Shacman trucks for Dangote as a precedent in the local industry.