Segun Ajayi-Kadir

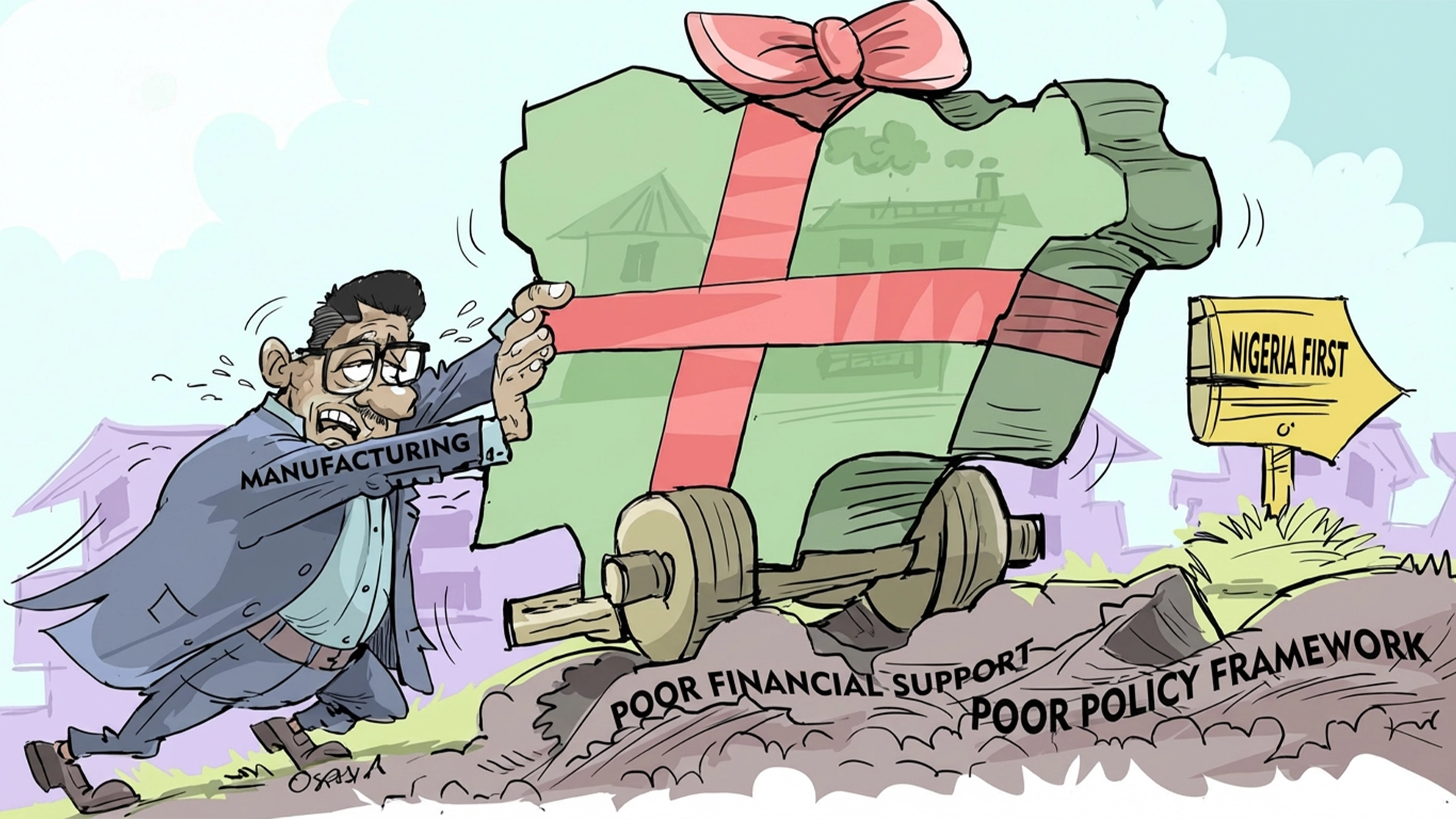

Manufacturers’ confidence in the economy has dropped further by 1.6 points to 51.9 points in Q2 2024 from 53.5 points recorded in Q1 2024.

This is a relapse following the improvement recorded in the previous quarter, showing that the sector is experiencing more difficult times.

This was revealed in the Manufacturers Association of Nigeria (MAN) CEOs Confidence Index (MCCI) for the second quarter of the year released yesterday.

Reading above 50 points indicates the expectation for economic expansion, while an index score less than 50 suggests deterioration in the operating environment.

The quarterly report attributed the decrease to the current performance of diffusion factors. While the indicators for the Current Business and the Current Employment Conditions further declined below the 50-point benchmark, dropping from 46.8 points and 47.5 points in Q1 of 2024 to 43.9 points and 47.2 points in Q2 2024, respectively.

The index of the Current Production Level fell from 52.8 points to 49.7 points which is also below 50-point threshold, underscoring a significant decline in manufacturers’ confidence regarding production levels during the review period.

The report also noted that all manufacturing indicators recorded unfavourable changes as in addition to the FX scarcity, high exchange rate and heightened inflation, the unfavourable macroeconomic environment was aggravated by the skyrocketed increase in electricity tariff, consistent increase in interest rates, perennial fuel scarcity and the nationwide industrial action during the reviewed quarter.

All of these the report revealed, grossly escalated the cost of manufacturing operations, distorted the manufacturing value chain, discouraged investments, increased job losses and reduced sales volume.

In terms of increase in production costs, the worst hit sectors are the wood and wood products sector, closely followed by the flood/beverages/tobacco sector and the electrical and electronics sector. Others are the basic metal, iron and steel sector, chemicals and pharmaceutical sector and the industrial plastic and rubber sectors.

“Production and distribution costs surged further by 24.4 per cent in Q2 from 20.7 per cent in the preceding quarter while capacity utilisation declined further by 14.1 per cent from 9.8 per cent. Production volume slid to 11.9 per cent from 10.1 per cent just as manufacturing investment slid to five per cent from 5.2 per cent.

“Manufacturing employment declined by 4.9 per cent from 5.3 percent while sales volume fell by 9.3 per cent compared to the decline of 7.2 percent witnessed in the preceding quarter. Cost of shipment rose by 17 per cent from 22.2 per cent.”

Top ten on the list of manufacturers’ challenges include multiple taxation; high energy cost/hike in electricity tariff/inadequate power supply; high exchange rate/ forex scarcity; high inflation; limited sourcing and high cost of raw materials; declining sales; high interest rate and low access to credit; insecurity; over-regulation by Government agencies and high transport costs.

“The analysis confirms the effect of the harsh macroeconomic environment on manufacturing indicators. Insecurity, rising energy costs and lending interest rates continue to reinforce inflationary pressure, thereby making the operating environment highly unfavourable and sales less profitable for manufacturers,” the report added.

Businesses in Kano (40), Rivers/Bayelsa (44.7), Bauchi/Benue/Plateau (45), Anambra/Enugu (48.1) Oyo/Ondo/Ekiti/Osun (48.8) industrial zones showed the lowest confidence in the economy as they were more affected the by the harsh economic conditions in Q2 of this year.

The report added that the 150 basis-point hike in the benchmark interest rate in May further escalated borrowing costs, restricting access to credit and discouraged productive investment in the manufacturing sector. “By the end of Q2, average prime and maximum lending rates for manufacturers had risen to 22.43 per cent and 32.73 per cent respectively.

“These are exorbitantly too high to promote productivity in the sector. In addition, the narrowing of the asymmetric corridor also reduced the incentives of Deposit Money Banks (DMBs) to lend to the manufacturing sector in the early periods of Q2.”

The report regretted that no manufacturing company can operate optimally or benefit maximally from economies of scale without adequate infrastructure like power and transport network. In addition, the sector’s productivity was limited by inadequate capital budget allocation, low domestication of capital projects, delay in the amendments of the 2007 Public Procurement Act and the inability to prioritise infrastructure in industrial hubs.

The manufacturers urged the government to tame inflation, stabilise FX and improving its access; promote energy security, ensure affordable lending rate and increased access to credit; address high and multiple taxation; upgrade infrastructure, ensure food security, promote local sourcing of raw materials, promote local patronage, address policy inconsistency and improve trade.