An aviation expert, retired Air Vice-Marshal Moses Onilede has revealed steps to be taken for Nigeria to overcome the challenges in the aviation sector.

Onilede in an interview with the Guardian shared an insight on aviation maintenance challenges and the evolution of Nigeria’s aviation industry.

He also spoke about the importance of domestic innovation, research and development to overcome longstanding challenges and ensure safety and efficiency in the sector.

Comparing your days in office and the present aviation industry, has anything changed?

The aviation industry has evolved significantly in recent years, especially with the rapid advancement of technology. However, some core challenges remain, such as the need for in-country maintenance capabilities and a reliable infrastructure for parts and repairs.

In my days in the Nigerian Air Force, we prioritised self-reliance, as demonstrated by projects like the GTCP85 APU test stand. Today, while there is more awareness and interest in domestic innovation, the industry still relies heavily on foreign facilities for high-level maintenance, which impacts both costs and aircraft readiness.

As an aircraft engineer, you must be aware that the bulk of the challenges facing the industry at the moment is caused by the lack of maintenance facilities in Nigeria. Why is this difficult to achieve?

Building advanced maintenance facilities requires substantial investment, skilled personnel, and regulatory support. The initial setup cost is high, and there is often a lack of confidence from investors due to fluctuating policies and forex issues.

Additionally, maintaining and upgrading these facilities demands a strong commitment to research and development. To overcome this, we need a coordinated effort between the government, regulatory bodies, and private sector stakeholders to ensure a stable environment for growth.

It is on record that you developed the GTCP85 APU test stand. Can you discuss this?

The GTCP85 APU test stand was a project I spearheaded during my service in the Nigerian Air Force. It was designed to provide a local solution for testing and maintaining auxiliary power units (APUs) without relying on foreign-made testers.

By developing this tool, we reduced downtime and maintenance costs for our fleet. The success of this project showcased the ability to create effective, indigenous solutions for aviation needs and highlighted the importance of in-house capability in maintenance operations.

What were some of the major challenges you faced during the design and production of the GTCP85 APU test stand?

One major challenge was the lack of local resources for aviation-grade manufacturing and testing equipment. We had to be creative in sourcing materials and developing parts.

Additionally, there was initial scepticism about whether we could achieve the necessary standards domestically. But through careful planning, collaboration with technical experts, and support from forward-thinking leaders in the Air Force, we succeeded in creating a reliable and effective test stand.

You once mentioned research on an AI-backed predictive maintenance system for aircraft. What will this do for the aviation industry?

An AI-backed predictive maintenance system will revolutionise how we maintain aircraft by identifying potential issues before they become critical. By analysing vast amounts of data in real-time, the system can predict component failures and suggest timely maintenance actions, which helps to avoid unplanned downtime and enhances safety.

For operators, this technology will increase efficiency and reduce costs, as maintenance can be scheduled more effectively based on data-driven insights.

Do you think this innovation will better the Nigerian aviation industry?

Absolutely. Predictive maintenance systems would be a game-changer for Nigerian aviation, where cost-efficiency is vital. With AI-driven predictive maintenance, we could reduce dependency on overseas maintenance facilities, lower operating costs, and improve aircraft reliability.

This technology aligns perfectly with the needs of our industry and could position Nigeria as a leader in aviation innovation within the region.

How do you think operators in the aviation industry can escape the menace of forex battles affecting their business as it concerns maintenance?

The key lies in reducing dependency on foreign services and parts by developing local capabilities. If we can produce more components and conduct high-level maintenance domestically, we lessen the impact of forex fluctuations.

Additionally, a supportive regulatory framework that encourages local innovation in manufacturing and maintenance can mitigate these challenges and promote self-sufficiency.

Operators often claim their aircraft are in good condition, but there are recent incidents of aircraft crashes. How can regulators be part of ascertaining the health of aircraft?

Regulators play a critical role in ensuring safety by establishing and enforcing rigorous maintenance standards. Conducting regular, unannounced audits, requiring detailed maintenance documentation, and certifying only qualified maintenance facilities can help ensure aircraft are truly airworthy.

Additionally, using data from AI-backed systems could assist regulators in monitoring trends and identifying potential risks more effectively.

What can be done to avert incidents of aircraft crashes in the future?

To prevent crashes, we need a proactive approach that combines rigorous regulatory oversight with cutting-edge technology like predictive maintenance. Ensuring that all operators adhere to high safety standards and fostering a culture of safety at every level of operations is vital.

Encouraging investment in training and technology will also ensure that maintenance teams and systems are equipped to keep aircraft in optimal condition.

What message do you have for young engineers in Nigeria who aspire to lead in aviation maintenance and technology?

My message to young engineers is to focus on continuous learning and innovation. Aviation maintenance is a complex field, and those who push boundaries will lead the future. Don’t be discouraged by challenges; instead, see them as opportunities to innovate.

Our industry needs bold thinkers who are willing to develop local solutions that address our unique challenges. With determination and hard work, they can drive significant advancements in Nigeria’s aviation sector.

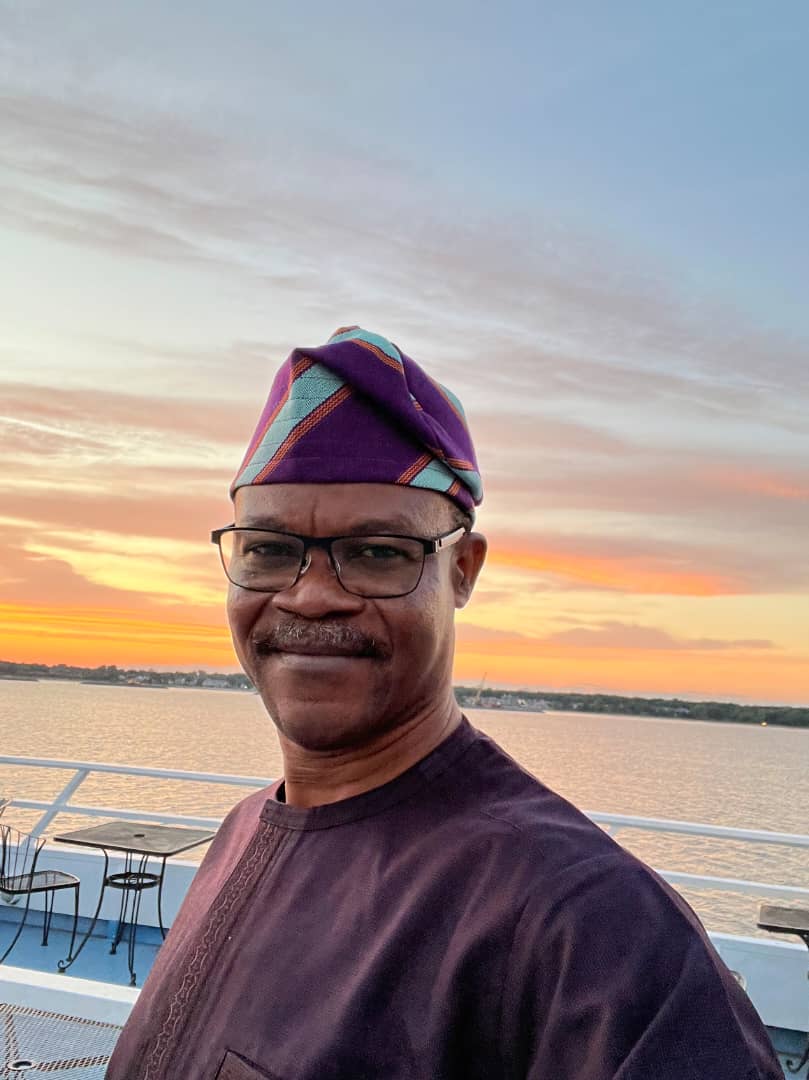

For the knowledge of our readers, who is Air Vice-Marshal Moses Onilede?

I am an experienced aviation professional who served for over 37 years in the Nigerian Air Force, specialising in aircraft engineering.

Throughout my career, I was dedicated to enhancing the operational readiness of Nigeria’s air assets and promoting self-reliance through projects like the GTCP85 APU test stand.

Currently, I am focused on advancing aircraft maintenance technology through AI-backed systems, and I remain committed to fostering innovation and growth within Nigeria’s aviation industry.