The Standards Organisation of Nigeria (SON), has said it will harmonise the production of various ventilators developed across the country to conform to uniformity in tandem with international standards and to achieve their manufacturing goals.

SON’s Director General, Osita Aboloma, urged the various inventors to ensure compliance to ISO 5080601/2/12/3020: Medical Electrical Equipment part 11, for Clinical Care.

According to him, adherence to standards will ease the processing of conformity assessment and certification of the products.

Aboloma said that certifying locally produced ventilators, air purifiers and hand sanitiser machines would put the nation in its pride of place in the clime.

Aboloma who stated this at Ilaro Polytechnic School in Ogun State, during the unveiling of local ventilators produced by the institution, commended the institution’s innovation in producing local ventilators, air purifiers and hand sanitisers machine amid the Coronavirus pandemic ravaging the world.

“We are partnering with the institute in ensuring that various machines produced in the country meet the required standards so as not to end up in the shelves.

“Standard is a common language all over the world. Once we are able to get the machines to standard, then we are there, ” he said

He commended all institutions that are producing ventilators, adding that they should ensure that the products meet the required standards specifications.

According to him, the unification will go a long way in saving Nigeria’s foreign exchange spent on importation of ventilators while also drumming support to the fight against COVID-19.

He also added that it would increase patronage of the equipment by citizens to improve their wellness.

Aboloma who was represented by the Coordinator, Ogun State Office 1, Jerome Umoru said the organisation would encourage the private sector to invest in such innovations to enable the inventors to go through the next stages of clinical trials and obtain the Nigerian Industrial Standard (NIS ), Mark.

He reiterated SON’s support towards sustaining local production of essential materials to fight the COVID-19 pandemic through quality assurance.

” We diligently assigned officers to inspect the ventilators and alcohol-based hand sanitisers being produced.

“We have one common standard for each product and we want to ensure that what we are producing here meets the standard and once it meets the standard, we will certify it. We will also continue to monitor their activities so that they do not rest on their oars in producing quality goods.

“I have just presented a copy of the Standard to the Rector of the Federal Polytechnic Ilaro, it is the ‘golden rule,” he said

According to him, once the institute meets the basic parameters and requirements, certification of the innovations will be fast-tracked.

“SON is ready to partner with all technical institutions especially those involved in the production of life-saving equipment and materials at this time, so that their products will meet minimum requirements of the relevant Nigerian Industrial Standards (NIS) and undergo certification under the Mandatory Conformity Assessment Programme (MANCAP) scheme”.

Aboloma disclosed that “upon certification, we will from time to time visit the institutional innovators in order to ensure that they continually conform to the requirements of the applicable Standards.

SON’s Chief Executive however indicated that very soon, Nigerian Consumers would be empowered through a product authentication scheme to determine the quality and conformance of products at the point of purchase, stressing that those without necessary certifications would be rejected.

Responding, the Rector, Federal Polytechnic Ilaro, Olusegun Aluko, said ventilators cost about N7 million to import, pointing out that possible partnerships with the private sector could help boost the production of ventilators in the country.

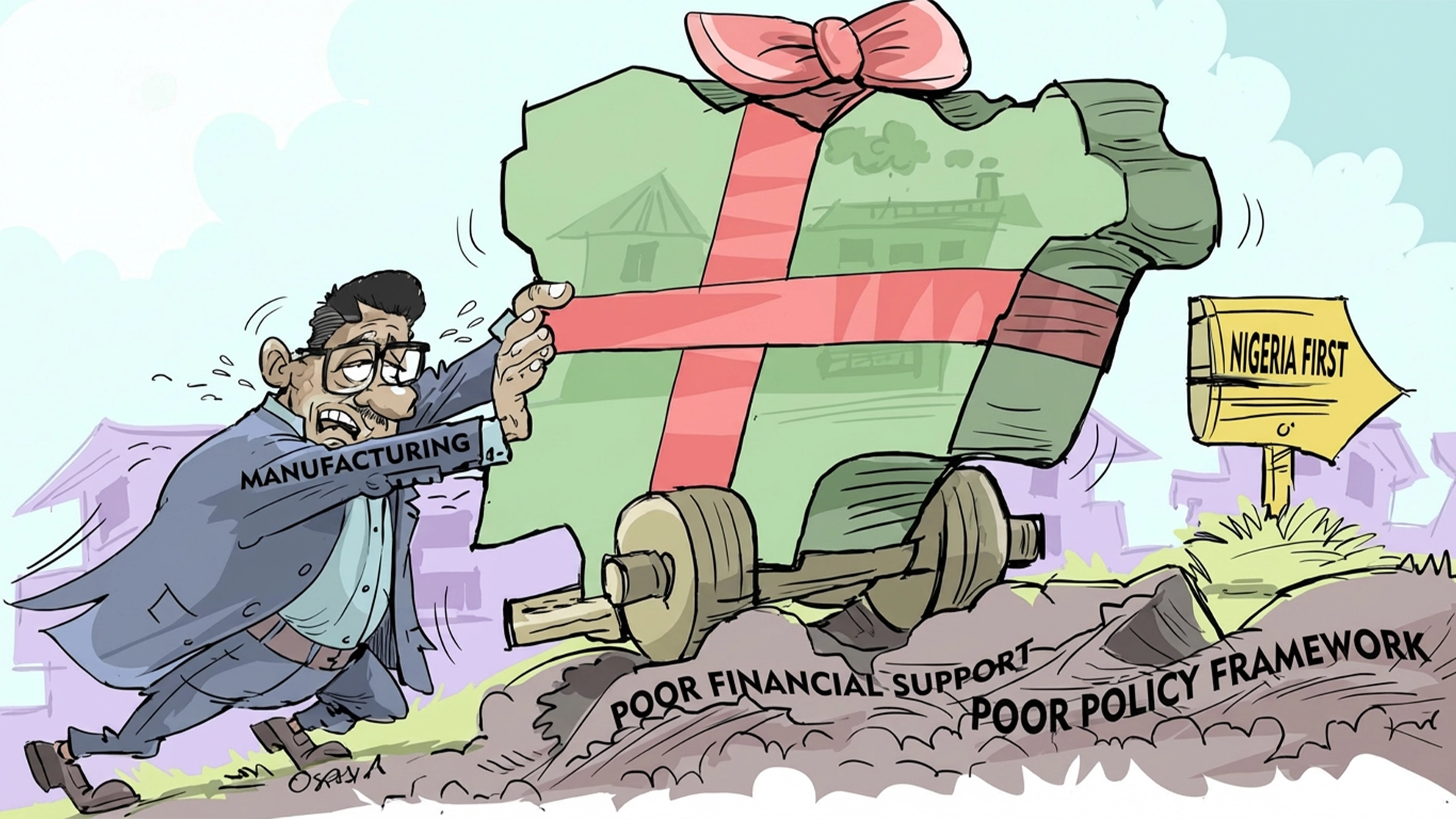

“The materials for manufacturing the ventilators were sourced locally; support to the noble innovation will make it more accessible and cheaper compared to imported one’s which are scarce, costly and would take longer to deliver”, he said.

He said with such partnerships, over 100 ventilators could be produced daily to help combat the COVID- 19 crisis in Nigeria.