Federal health institutions still owe pharmaceutical companies over N30bn

Federal health institutions still owe pharmaceutical companies over N30bn

•PMG MAN says COVID-19 boosted local production of medicines by 15%

•Frequent power failure, forex, multiple taxation, deplorable roads raise production costs by 300%

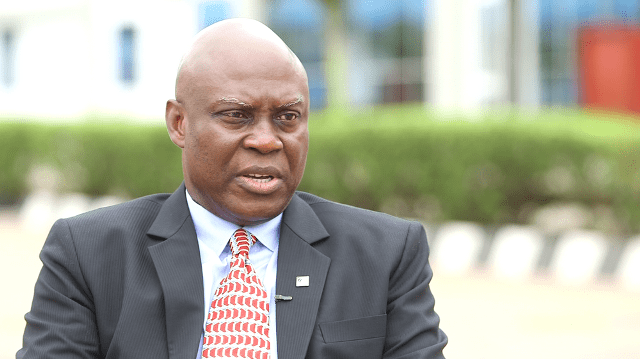

Ahead of Nigeria Pharma Manufacturing Expo (NPME) 2022, the Managing Director/Chief Executive Officer (CEO), May & Baker, Patrick Ajah, told journalist, in Lagos, that Federal Health Institutions (FHIs), including teaching hospitals nationwide, are still owing local pharmaceutical companies over N30 billion for drugs supplied.

NPME, scheduled for October 18 to 19, 2022, in Ikeja, Lagos, is organised by Pharmaceutical Manufacturers Group of Manufacturers Association of Nigeria (PMG-MAN), which is a sub sector of Manufacturers Association of Nigeria that represents all the manufacturers of pharmaceuticals and allied products in Nigeria.

Ajah, who is also the Chairman, 6TH NPME, at a press conference to announce the Expo with theme, “Advancing the Frontiers of Medicine Security in Nigeria, Expanding Local Pharma Manufacturing in the Era of AfCFTA”, said: “The House of Representatives have waded into the matter but the government-owned hospitals are still owing us over N30 billion for more than four months now. They owe May & Baker lots of money. Many of our companies cannot survive with such.”

He further explained: “On debt to companies, which also affects us, not much has happened. The members of the National Assembly when they heard it, Pharmaceutical Society of Nigeria (PSN) and PMG-MAN have been trying to push government to meet up with the obligation. The truth is that the government is owing some companies for more than four years,. I understand that the money is up to N30 billion, and this exactly what I meant when I talked about enabling environment.

“Many of our companies cannot survive if you owe us money for that long. You can imagine if you borrow money at a commercial rate and supply the government products that you have produced, and most of the products that are produced by local companies sometimes are 20 per cent less of what multi-nationals sell. So, they are affordable and the only way it can be affordable is if we sell at very low margins. The margins that local pharmaceutical companies make is probably 10 per cent sometimes of what multi-nationals make. So, if you make such low margin and they also owe you money plus the interests you pay to bank, its not going to work. So, we are still appealing to the government to please try and pay us.”

Former President, Pharmaceutical Society of Nigeria (PSN), Mazi Sam Ohuabunwa, had in a chat with journalists, in Lagos, in 2021, said the Society will name and shame tertiary health institutions owing pharmaceutical companies over N30 billion for medicines supplied under the Drug Revolving Fund (DRF) scheme.

He said local manufacturers benefitted from the COVID-19 pandemic as production capacity for essential medicines was boosted from 30 to 45 per cent and Nigerian pharmaceutical firms now supply over 60 per cent of medicines consumed in West Africa. Only 45 per cent of essential drugs are now imported because of COVID-19. We use to import 70 per cent of our essential drugs need before COVID-19. Now, the percentage of drugs produced in Nigeria has moved from 30 per cent to 45 per cent. Interestingly, 60 per cent of medicines used in West Africa are from Nigeria,” Ajah said.

Ajah said that members may soon be out of business because cost of producing drugs locally has risen by 300 per cent, in the past two months, due to frequent power failure, forex, multiple taxation, deplorable roads, among others. Ajah said: “We spend up to N150 million monthly on electricity. Most of us use gas generators but since the issue in gas supply, we spend on average N100 million on power generation alone and the cost of generating sets have gone up by 300 per cent.”

Executive Secretary, PMG-MAN, Frank Muonemeh, said NPME 2022 would enable a robust and comprehensive stakeholder engagement in the Industry, essentially as it concerns AfCFTA and the positioning of the industry for global competitiveness, post pandemic recovery.

AfCFTA, African Continental Free Trade Area, is a free trade area encompassing most of Africa. It was established in 2018 by the African Continental Free Trade Agreement, which has 43 parties and another 11 signatories, making it the largest free-trade area by number of member states, after the World Trade Organisation, and the largest in population and geographic size, spanning 1.3 billion people across the world’s second largest continent.

Muonemeh said the AfCFTA regime also has its own potentials for revolutionising the industry; however this is attainable, only – within the context which government allows for speedy infrastructural development and contextualised policy. Muonemeh said NPME offers all a platform to have robust discourse on the subject by experts.

He said: “AfCFTA could be positive or negative. Positive in the sense that it could provide opportunities for companies like ours to supply across West Africa, but the challenge or the negative part of it comes to play when we do not have enough capacity or enabling environment to stop products coming in from another country like Ghana. If some companies goes to Ghana, setup and manufacture cheaper products, because we have the population, the products are going to be flown into Nigeria. So, we might end up getter a strong competition and also have our capacity wasting if cheaper products are coming into Nigeria. So, it becomes important that the Nigerian companies begin to think of how to increase capacity, produce the things we are not producing now and instead of products being flown into Nigeria, we should have our products flown out to other West African countries and that is the positive side for us.”

Muonemeh added: “This is quite topical and forward thinking as we are recovering from the impact of COVID-19 on the economy and health sector. The pandemic was a reminder to us on the need for countries to prioritise their local pharmaceutical manufacturing sector, as there is a strong nexus between medicine security and national security, the vaccine nationalisation comes to mind.

“The pandemic has challenged us as a group to innovate, re-purpose and upscale our facilities to become competitive and more responsive inclosing the gap in access to medicine, as members are making SMART investments –buying machineries and looking at more innovative partnership and technology transfer.”

Muonemeh further explained: “One of the things I learnt during the pandemic is that it increased the patronage on local pharmaceutical manufacturing. I was at one event where my chairman made mention that it is now 45 percent and I can align with that. After the pandemic, before now partners do not look inwards to buy made in Nigeria products but the pandemic was a lesson for us and they started looking inwards and I can tell you that they are partnering with some local manufacturing companies to manufacture the medicines they are using in their interventions. When you check that ripple effects, you will discover that it makes a lot of sense. Due the challenges of supply chain, people that normally depend on imported medicines are now looking inward to the local pharmaceutical industries. So, I can tell you that we have moved from 70 percent to 45 percent and yes not yet empirical but with time, we will come up with data to back it up.

“PMGMAN, we are big and the challenge we have is getting data. Most products find their way in this country through informal route. Yes, we are having infrastructural challenges and those are the conversations we will be having with government policy makers that they need to do more and expedite action in this regard. The implementation of AfCFTA is more at the testing stage but they have started because there is a National Action Committee on Implementation of AfCFTA and a lot of consultations are on going on what should be liberised and what shouldn’t within the regulatory frame work. But in anyway they come, we will continue to hold fort to provide medicines for Nigerians.”

He said NPME is the largest exhibition of Central and West Africa on complete Pharma Manufacturing, put together by the PMGMAN and its partners – GPE India.

On local vaccine manufacturing, Ajah said: “It has been a very difficult route but we are seeing light at the end of the tunnel. Some of you may have watched the news like two week ago; the minister for health granted a press conference after the first meeting where he confirmed that possibly, before the end of this year, there might be a ground breaking of the vaccine manufacturing facility by Bio-vaccines.

“Bio-vaccines a joint venture company of May & Baker and the Federal Government that they suppose to restart local vaccine production in Nigeria. Nigeria was producing vaccines some years back in our office in Yaba; that was where the Yellow Fever vaccine manufacturing facility of Nigeria was but you know just like many other things, it was allowed to go to waste. So, the government wanted to restart it, so, in 2005, that company was formed.

“Although a whole lot of things have happened, the good news is that we have signed an Memorandum of Understanding (MoU) with the Federal Government to begin the building of a vaccine manufacturing facility. And like I said and confirmed by the minister for health, hopefully by the end of this year, there will be a ground breaking and once that is done, we are going to start manufacturing.

“In that meeting, we had one of our technical partners that visited the country and we had a meeting with the minister for health, so we have a very good understanding that that project is going on and once its done, we believe that in two years time, we will begin to manufacture vaccines in Nigeria. So thank you so much for the support that May & Baker has had through this process and I will like to say that Biovaccine is here to stay and by the Grace of God, we will start manufacturing our own vaccines.”

On the capacity of local manufacturers and how much of these are being utilized, Muonemeh said: “I will like to make some clarification here, most local manufacturers are focusing on products that the greater number of Nigerians will need, so we are not focusing on highly research-driven products. So, you think of products like Paracetamol, essential medicines are where we are focusing on, but I will like to say that some of our capacities are still under utilised.

“Essentially to a large extent, I think we are using 50 to 60 percentage of our capacity. So, we still have excess capacity that can be utilised and the reason is despite the fact that these products are produced in Nigeria and are affordable, we still have a lot coming from outside. Some of the products are still being imported and that is why the National Agency for Food and Drug Administration and Control (NAFDAC) said that if we have products that are being made in Nigeria, and you are still bringing the same products, after five years you would have to make them locally. Those are very good initiative because that is the only way this excess capacity can be utilised.

“Just like most Nigerians trust the Paracetamol made in Nigeria than the ones imported, that is what we want to encourage for many other products. So, any product that a local manufacturing company is making, we should try to patronise our own rather than importing. Once that is done, we will be able to utilise much of our capacity. NAFDAC is very thorough, so if NAFDAC approves any facility, they must have looked into the Good Manufacturing Process (GMP) requirements at least to be able to make the medicines.”

On many challenges of local manufacturers, Head Marketing, Fidson Healthcare Plc., Friday Enaholo, said: “Enabling environment will allow us to increase in capacity, increase in research and development. Let us face the facts, when you talk of human capacity Nigeria has it. I read on the media that about 5,000 pharmacists are leaving the country every year. This is human capital that we can make use of here, but because we have not expanded in research and development well enough to provide jobs for everybody. So, companies are going to utilise more money in research and development and improving capacities if government provides some of these other things like power. Some big companies presently are spending over N150 million in a month on power alone and this is challenging amongst other challenges.

“The truth is that if such a facility should continue to run, we should find a way to pass it on to the consumer, because when you don’t, you shut down and some of our companies are almost shutting down. We all need to get together, find ways we can leverage each other’s collaborations and make things better. We can collaborate through local manufacturing arrangements, contract manufacturing, especially for smaller ones who are not able to continue.

“Around 75 percent of Nigerians pay out of pocket expenses to be able to access health care and most times our insurance policy does cover them, so you cam imagine the ripple effects if you are to transfer those costs to the consumer. Most of these companies are holding fort and the only reason we are still in this business is that we weigh cost benefits and huge investments we have put on over the years that runs in millions of dollars. Companies are spending this money, holding the fort and not transferring it to the consumers because when they do, they won’t be competitive anymore and when you are no more competitive, you go down and the facility will shut down too. So, pharmaceutical manufacturers are patriots and that act of patriotism is the only thing that keeps you awake in doing this business, because it is no longer about profits anymore.”

Manager, JUHEL Nigeria Limited, Mrs. Chika Udeozor, who is also a member of organising committee NPME 2022, said: “We all know that health is wealth and most times Nigerians feels we are inferior because we do not believe in made Nigeria. If you go to the markets, our products are not increasing as it should and a lot of factors play roles, which the pharmaceutical industries are facing like power, which has already been mentioned, exchange rates, cost of raw materials coming in because we do not have most of the raw materials, then the congestion in the ports.

“We also talk of the funds the government owes us and then the taxation, all these factors hinder the growth of the pharmaceutical industries. We are trying our best because whatever we produce in Nigeria is 100 percent okay; with NAFDAC always on our neck visiting the facilities here and there, and checking every product, making sure everything is good. The only thing is that we cannot avoid the fakers around of which they are even working on it. NAFDAC will soon bring out the policy and I believe that these fake products will be a by-gone issue by then. Like our chairman said, when you visit the facilities outside the country, you will not want to take their products, rather you will prefer the ones made in Nigeria.”