In recent years, Nigeria has placed significant emphasis on digital innovation. We have seen a rise in delivery apps, freight-matching platforms, automated inventory systems, and data dashboards that promise new levels of speed and visibility. These are meaningful steps forward.

However, while technology provides coordination and intelligence, it does not move goods independently. What drives logistics performance is a combination of people, physical assets, and infrastructure—supported, not replaced, by technology.

This is the essential grey area in our national logistics conversation. To build a competitive and resilient logistics system, Nigeria must balance innovation with investment in the human and physical layers that underpin the movement of goods.

Logistics as an economic enabler:

Logistics is foundational to trade and national productivity. It determines whether farmers access markets, whether manufacturers can obtain inputs, and whether consumers can afford essential goods. Nigeria is a maritime-driven import economy—over 95 per cent of our imports arrive through seaports—and distribution across the country is predominantly road-based, accounting for over 80 per cent of goods movement.

These realities mean that port efficiency and road conditions significantly influence logistics costs and delivery timelines. The World Bank’s 2023 Logistics Performance Index, where Nigeria is ranked 88th globally (compared to South Africa – 19th, Egypt – 57th, Benin – 66th), highlights infrastructure reliability, clearance processes, and delivery consistency as key improvement areas. These are structural challenges. Digital platforms alone cannot resolve them.

The human element: The often overlooked asset

Every logistics operation relies on people who execute and interpret physical processes:

Drivers and dispatch riders; Warehouse and hub supervisors; Route planners and fleet controllers; Customs and port clearance professionals and Safety, maintenance, and compliance teams.

Their decisions, training, and discipline determine performance outcomes. Yet, across the industry, investment in workforce development remains limited. High turnover, limited training for dispatch staff, and inconsistent safety culture continue to undermine service reliability and operational efficiency.

A well-trained driver who understands route planning, customer handling, safe loading, and cost management is a critical asset. A well-structured operations team can deliver stronger performance than platforms alone. Strengthening this human capability is both a cost-saving and service-improving strategy.

Physical assets: The real carriers of value

Nigeria’s logistics networks are built on a diverse fleet: Motorcycles and tricycles for dense urban deliveries; Vans and light trucks for last-mile and store delivery; Rigid trucks and articulated trailers for interstate haulage; Cold-chain vehicles for pharmaceuticals and food and Barges and coastal vessels for water-based transport routes.

Software may optimise routes and fleet utilisation, but it cannot replace the vehicles themselves. A company with inadequate or poorly maintained fleet assets will struggle regardless of the digital tools it adopts. Similarly, without warehouses, cross-docking facilities, and reliable power, inventory and throughput efficiency remain constrained.

Infrastructure and policy: The structural context

Several systemic issues currently shape logistics performance: Port congestion and slow cargo evacuation, which increases dwell time and costs. Congestion and delays at ports like Apapa cost businesses an estimated $5.8 billion in lost earnings annually.

Road infrastructure gaps, particularly along key trade corridors. Poor road networks cost the Nigerian economy an estimated $1 billion annually (World Bank). The LCCI gives a higher estimate of $8 billion for total inefficiencies. Volatility in fuel prices, which directly affects cost per kilometer. Regulatory inconsistencies and multiple taxation across states, affecting fleet deployment and route planning. Addressing challenges in informal settlements, leading to delivery delays and failed delivery attempts.

This is why logistics costs in Nigeria can represent up to 40 per cent of the final cost of goods, compared to 9–10 per cent in more efficient economies. The issue is not a lack of technology. It is the cost of compensating for weak infrastructure.

These challenges require coordinated policy and investment interventions. Technology can improve coordination—but it cannot substitute for infrastructure, regulatory clarity, or stable operating environments.

A balanced path forward

To create a logistics system that supports business growth, reduces supply chain costs, and ensures reliable service delivery, Nigeria can take a balanced and strategic approach. The future of logistics in Nigeria is neither purely digital nor purely manual. It is phygital — a deliberate integration of physical assets, skilled people, and technology:

Strengthen road and port infrastructure along critical economic corridors.

Establish workforce development standards, covering dispatch, driving, safety, and operations. Support access to fleet financing, enabling companies—especially SMEs—to invest in reliable vehicles. Enhance regulatory coherence across states, particularly regarding last-mile delivery assets. Promote technology adoption as an enabler, focusing on visibility, planning, and performance tracking.

Conclusion.

Technology remains vital. It improves transparency, speeds decisions, and enhances coordination. However, technology performs best in environments where infrastructure is functional, assets are available, and people are skilled. To unlock the full benefits of digital logistics innovation in Nigeria, we must therefore focus on strengthening the physical and human foundations on which logistics operates.

In doing so, we position our logistics sector not just to serve today’s needs, but to support the broader economic growth agenda—efficient trade, competitive manufacturing, robust agriculture supply chains, and accessible consumer markets.

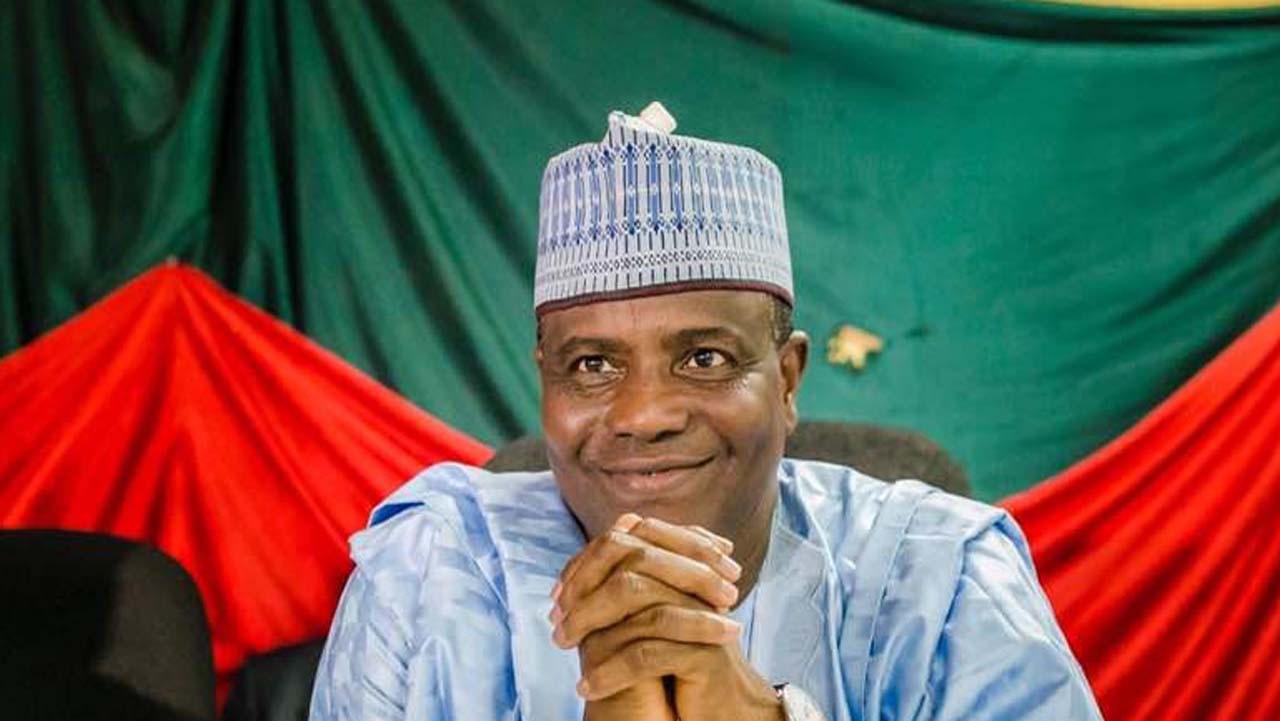

Preghafi, a logistics and strategy professional with experience in supply chain operations, wrote from Lagos.