In an insightful conversation with The Guardian’s Ifeanyi Ibeh, Olufemi Theophilus, a manufacturing expert with over 12 years of experience, sheds light on the evolving challenges and opportunities within Nigeria’s Fast-Moving Consumer Goods (FMCG) industry. With his vast knowledge of supply chain dynamics, regulatory complexities, and the rise of advanced technologies, Theophilus delves into the impact of Nigeria’s infrastructure deficits, foreign exchange fluctuations, and talent shortages on the sector’s growth. He also explores how FMCG companies are adopting innovative solutions to meet consumer demands, maintain sustainability, and remain competitive in a volatile market.

How has the volatility of Nigeria’s supply chain, particularly in raw material sourcing and distribution, impacted manufacturing operations in the FMCG sector?

The volatility of the Nigeria’s supply chain has led to incessant pricing increase and product availability issues. Companies now have to keep more inventory and keep multiple RM suppliers to keep up with the volatility. Also, this volatility has led to shutting down of certain distribution channels that have now become unprofitable due to increased costs of inputs including gas and electricity.

Nigeria faces significant infrastructure challenges, especially in transportation. How do poor road networks, inconsistent power supply, and logistics bottlenecks affect FMCG production and distribution efficiency?

The regulators in the food and drugs space are doing a great job at providing guidance to the FMCG’s but there is a lot of overlap and duplication between the agencies that needs to be resolved by the government to help the FMCG’s have an increased speed-to-market. There is definitely a need to review the policies relating to regulation in the FMCG space.

To navigate the current complexities in the regulatory space, FMCG companies leverage the use of consultants that have experience with relating with the various multiple regulators and this prevents the possible bottlenecks.

How do you balance maintaining high production volumes while meeting the evolving tastes and demands of Nigerian consumers, especially with the rise of health-conscious trends?

With the advent of advanced technological innovations including machine learning and AI, FMCG’s are using AI and machine learning capabilities to understand what consumers’ buy, where they buy them, and how they buy them. This helps to reduce streamline the manufacturing plants to make only what is needed by the consumers and when it is needed. The adoption of these modern technology, though not widespread yet, helps the companies to reduce losses associated with excess inventory. Companies are also adopting digitaization of reports and automation of machinery which help to reduce paper costs and overhead costs associated with human intervention in the processes.

How do fluctuations in the prices of raw materials, foreign exchange rates, and inflation affect the profitability and pricing strategies of FMCG products?

Raw material (RM) prices, forex flunctuation and inflation have really hit hard on the profitability of FMCG’s so one of the ways that FMCG’s are tackling this challenge is by RM localization of the major RM’s that are being used. For example, FMCG’s are moving fast on Sorbitol localization to prevent reliance on.

What challenges do you face in recruiting and retaining skilled talent in the FMCG sector, particularly in the areas of manufacturing, operations, and supply chain management?

At this time, there is a dearth of well rounded supply chain professionals because there is no dedicated training for supply chain professionals in the country though , this exists on the continent. Also, may professionals do not have an understanding of the manufacturing space because it is considered as a ‘rugged’ space. Recruiting and recruiting talents in the manufacturing space is challenging because the recent graduates consider it cumbersome when compared to the tech space including fintech so they will opt for those seemingly more lucrative fields. For other nodes of the supply chain, talent retention is relatively better compared to manufacturing.

To overcome this human resources challenges, companies tend to rotate employees across the various nodes to enable technical mastery which brings job satisfaction. Additionally, we keep a line of sight to the overall business goals so that the employees see their contribution to the bigger picture and they will not see themselves as just shop-floor workers.

With the increasing focus on sustainability, how are FMCG companies in Nigeria adapting to more eco-friendly practices in manufacturing, and what challenges do they face in this transition?

We now have recylable packaging in the FMCG products and alot of money is being spent by the FMCG’s to educate the consumers on how to recycle materials. Recently, some start-ups are focusing on recycling plastic bags from FMCG products and they have recieved grants from both the government and the FMCG’s themselves.

Some FMCG’s have removed non-environmental chemicals like Phosphates but this poses some challenge with how the production process will run smoothly. FMCG’s are re-designing their processes to run smoothly without the non-environmentally friendly raw material.

Also, FMCG’s are focusing on ways to reduce water and energy usage, ways to recyle of water, waste segregation methods and renewable energy usage (especially solar energy).

How has the integration of advanced manufacturing technologies, such as automation and Industry 4.0, been received in Nigeria’s FMCG sector, and what challenges hinder widespread adoption?

Advanced manufacturing technologies like IoT and Industry 4.0 is gradually being accepted in the Nigerian FMCG space but it will take a few years to get to a level of full adoption.

There are many factors hindering widespread adoption of advanced technology but one key reason is the infrastructural deficit that we have as a country in terms of power and internet.

The advanced technologies like IoT, Industry 4.0 and automation rely alot on cloud computing which in turn rely on stable internet which relies on stable electricity which is not available. One other reason of the low adoption rate of advanced technologies is that those technilogies are usually reliant on forex which is not readily available unlike the older technologies that are readily available.

How do you navigate the intense competition from both local and international FMCG brands, and what strategies do you employ to maintain market share in such a dynamic market?

Maintaining market share in a highly competitive and dynamic market like Nigeria requires tact. First, product integrity is important to drive trust with the consumers – this means that the product should do what you stated that would do. Secondly, product value and superiority communication is important especially for multinational FMCG’s so that consumers can know why they are paying higher for the products of certain companies. Another strategy is that multinatinals also have a range of products to cater for a wide range of consumers from the low-income to the high-end customer. This was they get a share of the market across board.

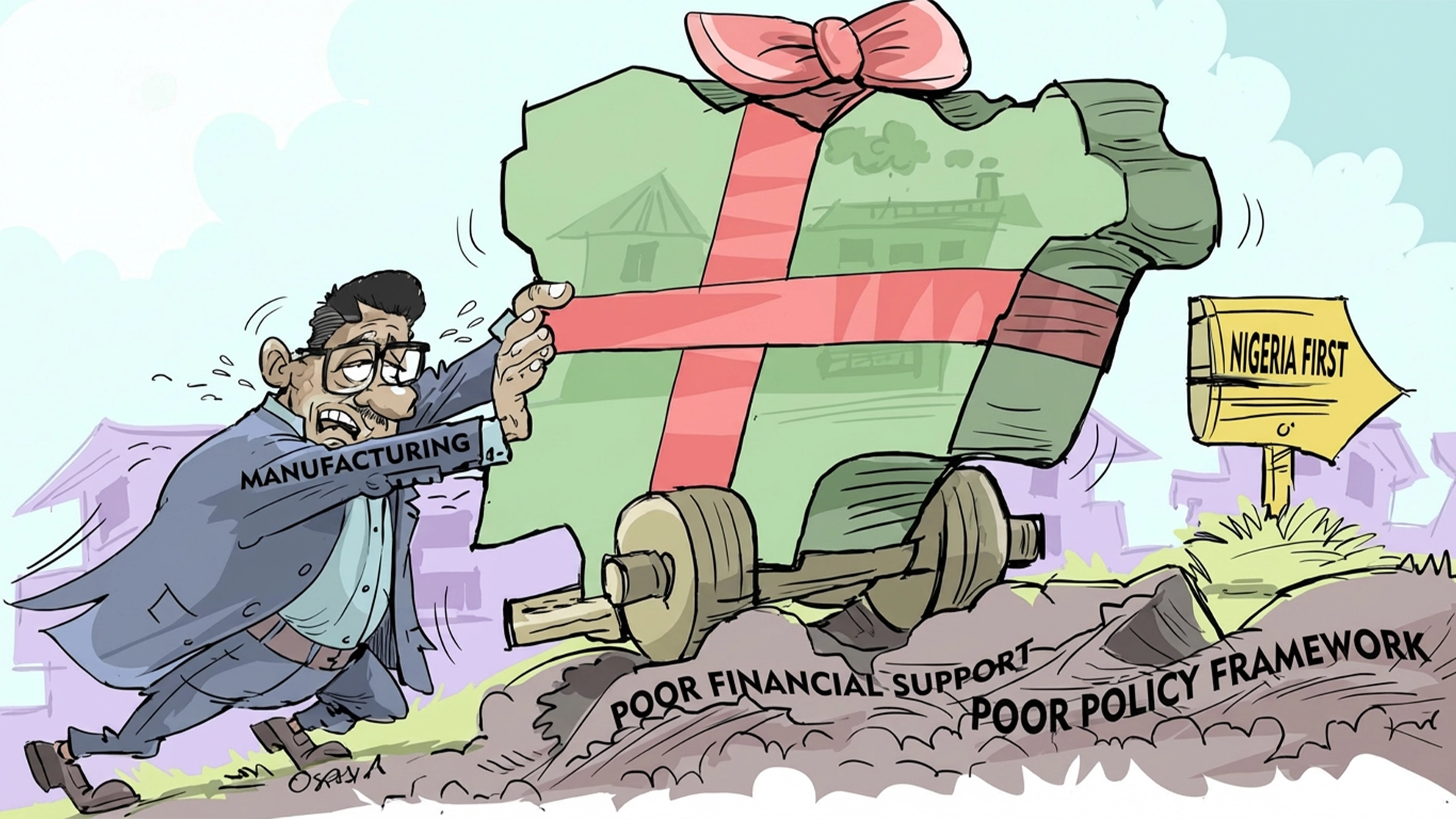

Given the frequent policy shifts and economic instability in Nigeria, how do FMCG manufacturers stay agile and resilient in managing risks while ensuring continuous production and market relevance?

FMCG’s now have dedicated crises management teams (CMT) along their government-relations (GR) teams to churn out mitigation actions to any policy shift relating to their areas. Also, FMCG’s remain agile by reviewing their Business Continuity Plans (BCP) more frequently than before (COVID taught us a lot of lessons). Finally, more robust scenario planning is incorporated into the BCP’s.